Since I started my business life in parallel with my master’s degree, while learning, I had the opportunity to question my processes and generate ideas. One of my observations that constitute my thesis was that while the use of 3D printers before the production of the projects was quite high, many product development engineers did not have sufficient knowledge about additive manufacturing technology. To increase efficiency and avoid any wrong selection of users, I decided to prepare simple selection application

Motivation

The efficiency of additive manufacturing technologies depends on the selection of the right technology and material for the application. Due to insufficient information, wrong additive manufacturing technology can be selected.

Aim

The aim of this project to examine the use of advanced rapid prototyping technologies and method choices in automotive industry. Prepared very simple application for 3D Printer technology selection application based on these examination and user neededs.

Responsibility: Owner of the idea and project

Discover

With the development of layered manufacturing technologies, the application of rapid prototyping technologies on different sectors has become widespread. The emergence of different technologies in this field and changing their usage according to expectations have also extended the application areas by providing a clearer definition of the deficiencies and advantages of technology. Technology; It is used in many different industries such as medical, aerospace and automotive. Especially in the process of prototyping and testing stages in the design process with the increase in the use of the automotive industry is becoming widespread.

For my thesis research, I investigated many additive manufacturing application as spare part, prototype part or serial production for low volume production in the automotive industry. The study shows that rapid prototyping technologies have an important place in automotive, especially in pre-production period. Determination of possible design errors before production, visual assessment, function analysis, liquid analysis, installation evaluations and so on. provides many advantages. However during these researches, I realized that we actually use additive manufacturing technology very limited as a company. Due to the limited knowledge of the possibilities of the technology, there was a misconception that only parts suitable for prototyping can be produced.

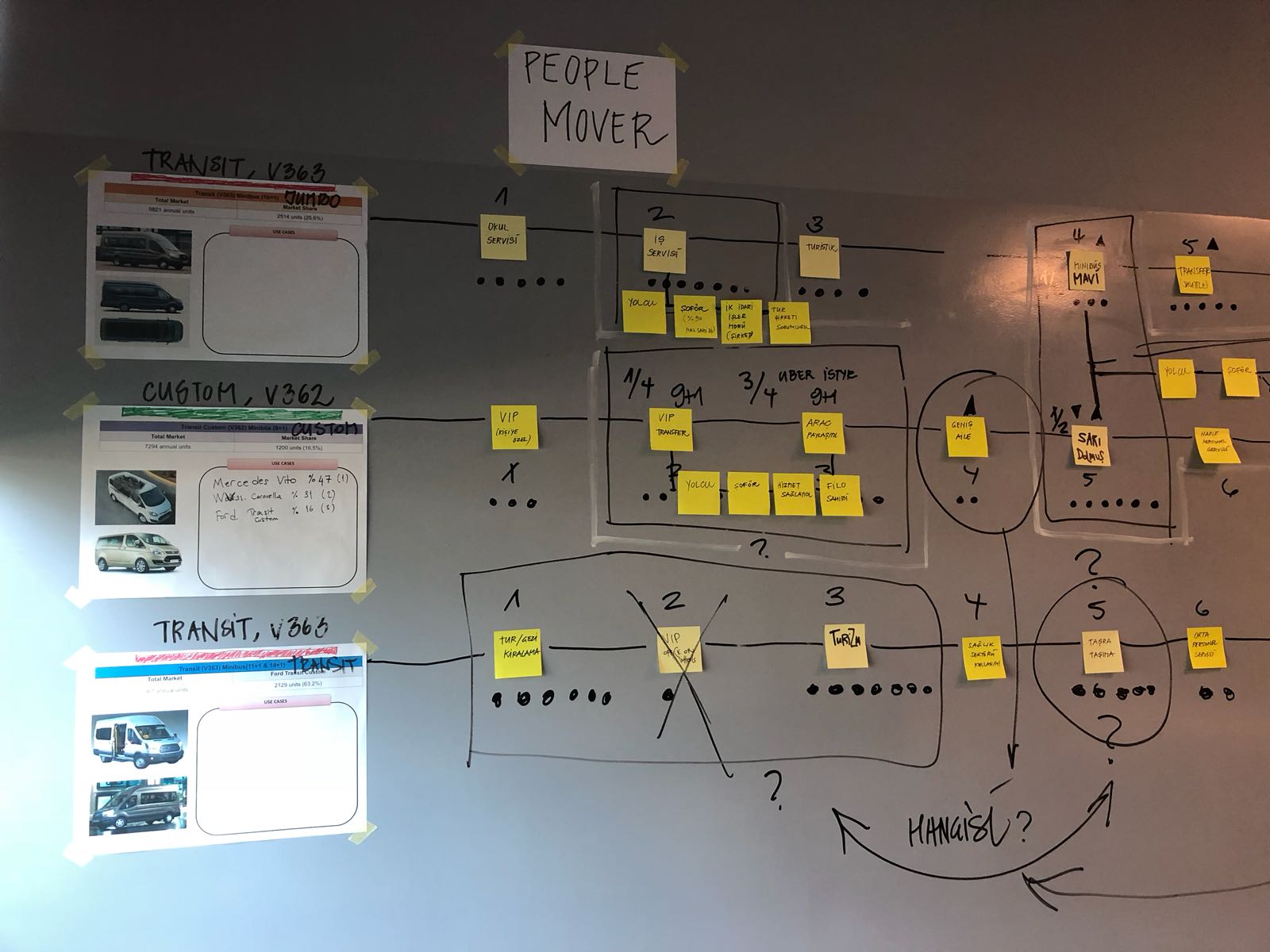

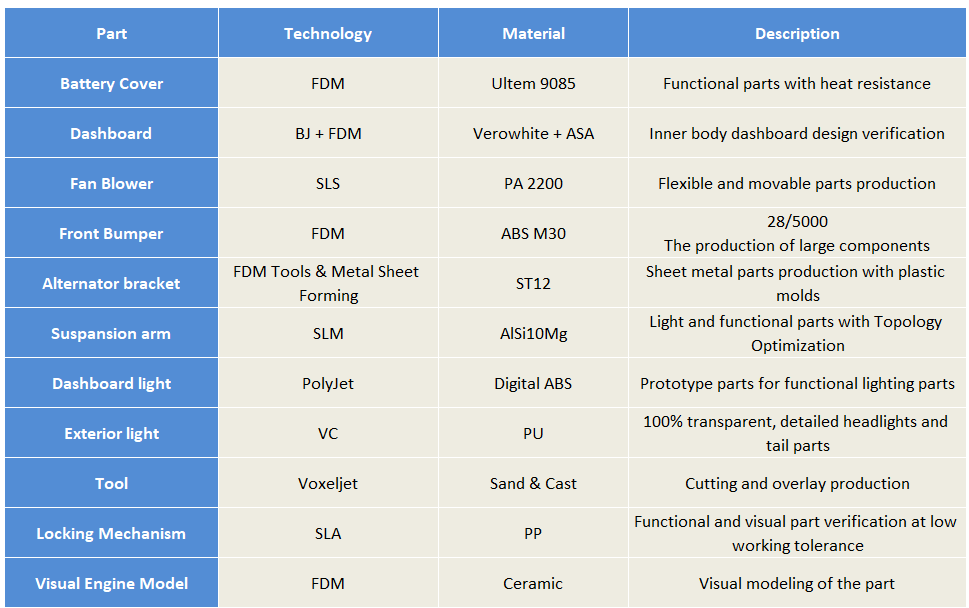

In order to answer the question of which areas we can use in the company and further, I have examined the uses of the last project. For this project, I have prepared a detailed analysis of which departments produce which parts for which purpose. To create more examples, I have searched the 3D printed parts made internaly and externally in the last 5 years. In line with these information, I created a table that combines the different production criteria and engineering needs of 3D printer technologies.

Also I investigated different automotive companies such as Volvo, Daimler, Mercedes, Mini Cooper and Ford, their applications and their collobration with additive manufacturing companies as case study. I saw that the most used technologies are FDM , SLS, , SLA, SLM and BJ.

As a result of these studies, I have classified the additive manufacturing technologies in the automotive sector for use;

♦ Concept Vehicle

♦ Low volume production/prototype

♦ 3D Components

♦ Spare part

♦ Fixture

♦ Production

♦ Customization

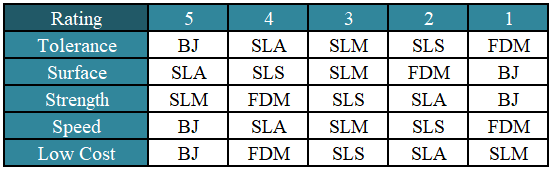

According to these uses, I determined the selection criteria according to the features carried by the parts and the areas used.

♦ Material

♦ Strenght

♦ Lead time

♦ Surface quality

♦ Tolerance

♦ Cost

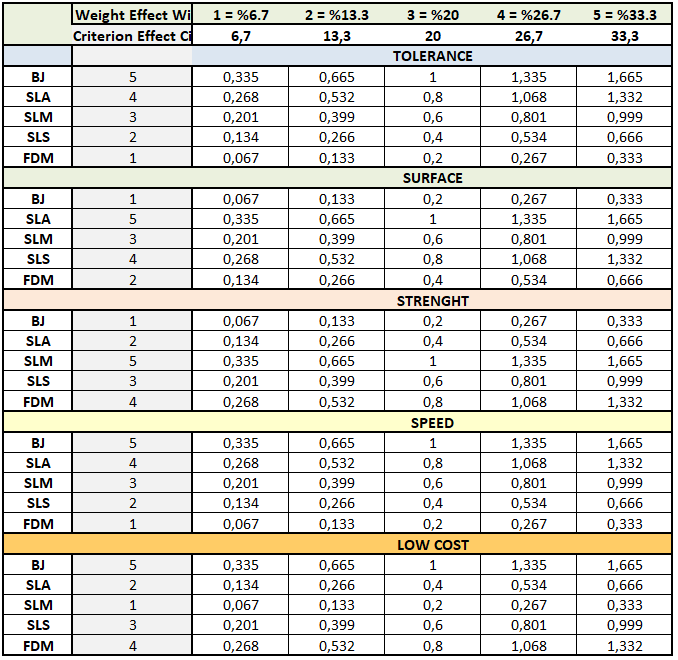

I created a comparison chart using the superior advantages and ranges of different advance manufacturing technologies. Also I prepared a selection matrix based on multiple selection criteria method to use in software algorithm.

Ideation & Prototype

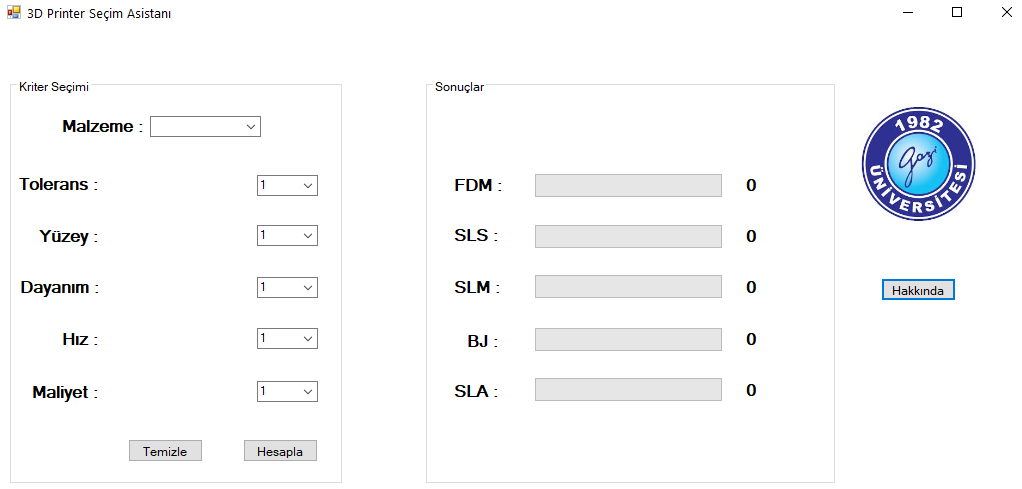

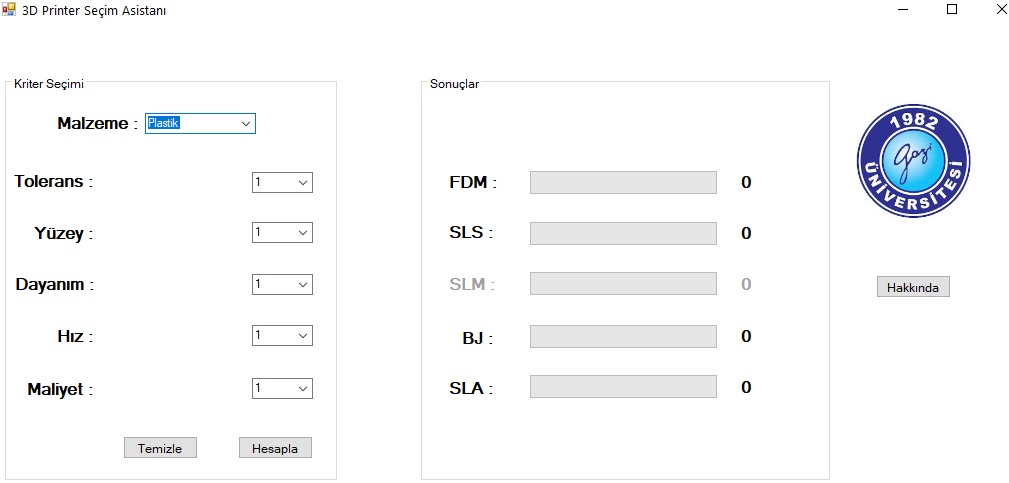

First of all, as the main target of the project; The app should be easy to understand and to use even for a person who is not familiar with these technologies.

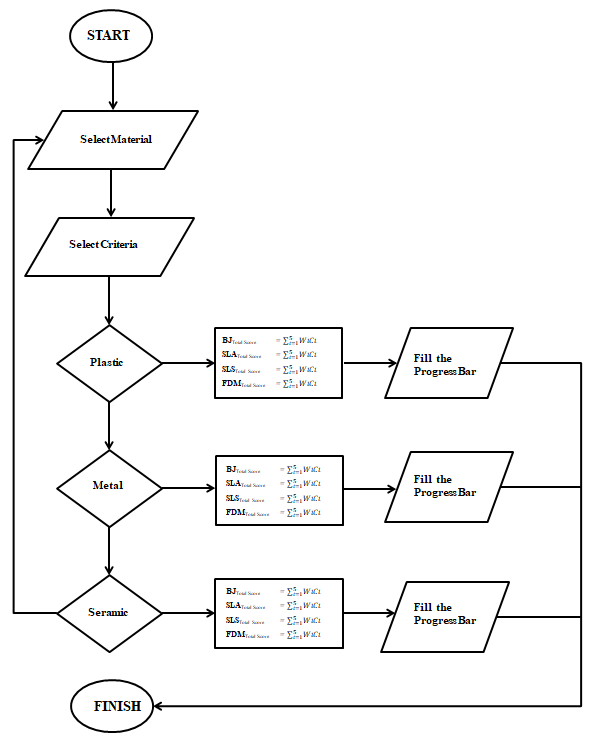

According to decision matrix I prepared algorithm of program with simple sketch. The selected selection criterias should be user-selectable.

The user should be able to see the results for the criteria she7he chooses without dealing with the intermediate pages on the same screen.

With this algorithm, I defined my one page application started writing code in visual studio with the support of my friend who is software developer.

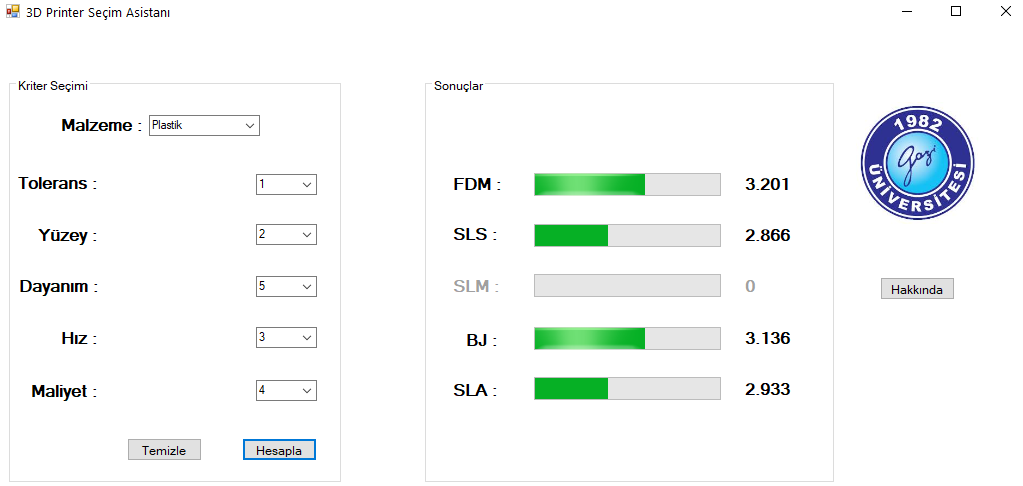

Test

First of all, I tested the application with the requirements of the case studies from my research in order to test the accuracy of the data and the algorithm and verified it with the match of the selected technology. Then I started the user test using the needs in the company.